Usage Guide for Clifton Accelerator

Addition of Clifton Accelerator to Clifton Hypalon Adhesive gives maximum strength in repair work, increases heat and chemical resistance, speeds up the tack between coats, and shortens full bonding time. We recommend its use for air-holding repairs in boat chambers and floors, and items that will be subjected to a lot of stress, such as D-ring patches, EasyCarry Handles, and foot cups. This is the same combination used in building NRS Pennel Orca inflatables.

| Ounces of Clifton Hypalon® Adhesive |

Milliliters of Accelerator * |

Approx. Drops of Accelerator ** |

| 2 | 0.4 | 10 |

| 4 | 0.75 | 20 |

| 8 | 1.5 | 40 |

| 16 (pint) | 3.0 | 75 |

| 32 (quart) | 6.0 | 150 |

| 128 (gallon) | 24.0 | 600 |

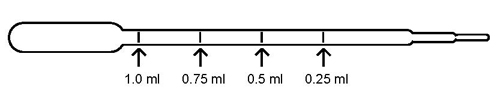

The correct mixing ratio is 0.8 ounces (24 milliliters) of Accelerator to one gallon (128 ounces) of adhesive. We’ve made measuring small quantities of the Accelerator easy with the included disposable transfer pipette. The stem of the pipette is marked in 0.25-milliliter graduations (see figure below).

Measure out only the amount of adhesive you will use within a 4-hour period. Add the right amount (from the table above) of Accelerator and mix thoroughly. After four hours, mixed adhesive that you haven’t used should be discarded.

Note 1: This is a case where more is definitely not better! Using more than the recommended volumes of Accelerator will cause problems with the glue bond.

Note 2: The Accelerator is water sensitive and will crystallize when exposed to moist air. Keep tightly capped as much as possible. If you do get some crystallization, the remaining liquid portion is still good.

*The formula used to create this column is:

Milliliters of Accelerator = (Ounces of Adhesive x 24) / 128

** If you don’t have the graduated pipette, you can use a regular eyedropper (found at most pharmacies) to dispense the Accelerator. There are approximately 25 “drops” in a milliliter. (See diagram below.)

Note 3: Clifton Accelerator can be mixed with Clifton Urethane Adhesive (Item # 1901). It will not increase the bond strength, but will increase heat and chemical resistance of the bond. If the material bonded will be subjected to temperatures greater than 140º F, use of the Accelerator is recommended.

NRS Gift Card: Always Fits, Always Wanted

NRS Gift Card: Always Fits, Always Wanted